You can rely on our experienced sales team who proficiently tackle almost any issue related to coatings.

We offer competent support throughout the entire process chain as reliable hands-on advisers.

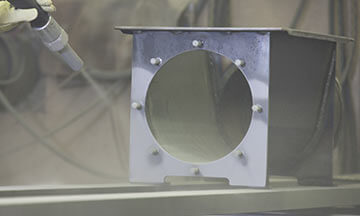

Starting by determining the ideal design of the parts to be coated, through to choosing the best lining to address your specific needs.